The testing of natural frequencies on brake discs in series production is becoming increasingly important for quality monitoring in series production. Many OEMs now require 100% quality control from their suppliers. The test is carried out in different production stages. Both raw parts and finished brake discs are tested.

In connection with the changed conditions in electric cars and in view of the future Euro 7 standard, more and more coated brake discs are being used. The quality requirements are also increasing and with them the testing requirements. The advantage of 100% quality control is obvious. Systematic changes in production are detected at an early stage and parts with an anomaly can be sorted out directly. The significantly reduced use of personnel is also an advantage for the manufacturer himself. The test parameters for series monitoring are determined in advance using FEA calculations and are validated in laboratory with manual testing systems.

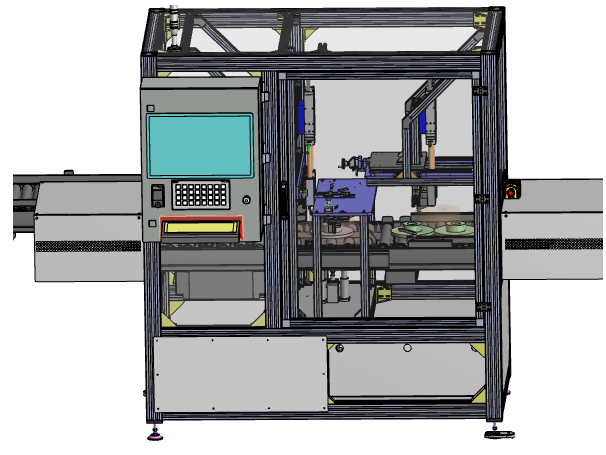

RTE has been supplying test systems for measuring and testing of natural frequencies for many years, from manual test equipment to fully automated test systems for 100% quality control. Reproducible and stable measured values are a matter of principle for RTE test systems.

The fully automatic test systems can be supplied as a complete machine or for the integration in cooperation with machine suppliers or integrators. The systems have been continuously developed and can be used for a wide range of parts with short cycle times. Production with a product mix is also possible. Product tracking and data export (e.g. according to Q-Das Standard) are available.

Damping resp. the Q-Factor (reciprocal value of damping) is considered more and more as a quality characteristic in series production for brake discs. As a reproducible evaluation of damping/Q-Factor takes more time than an evaluation of natural frequencies a random inspection is recommended.

Please contact us, we are ready to support you. Send an email to info@rte.de.