ACOUSTIC MATERIAL TESTING – WE HEAR QUALITY

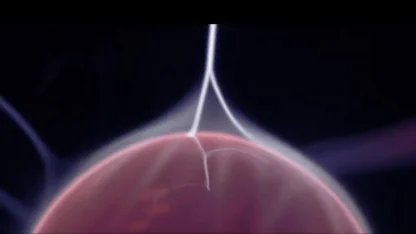

Acoustic testing technology is an environment friendly and resource-saving testing technology and therefore your investment in the future.

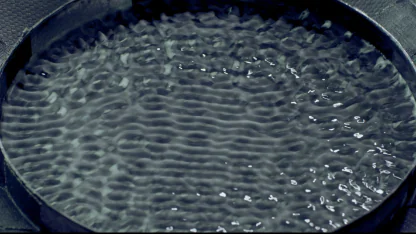

As a comparative testing technique, it automatically separates good and defective components from one another. Provided that the test object can be stimulated to vibrate and the faults to be monitored have an acoustic relevance. This often works much better than expected, especially in series testing!